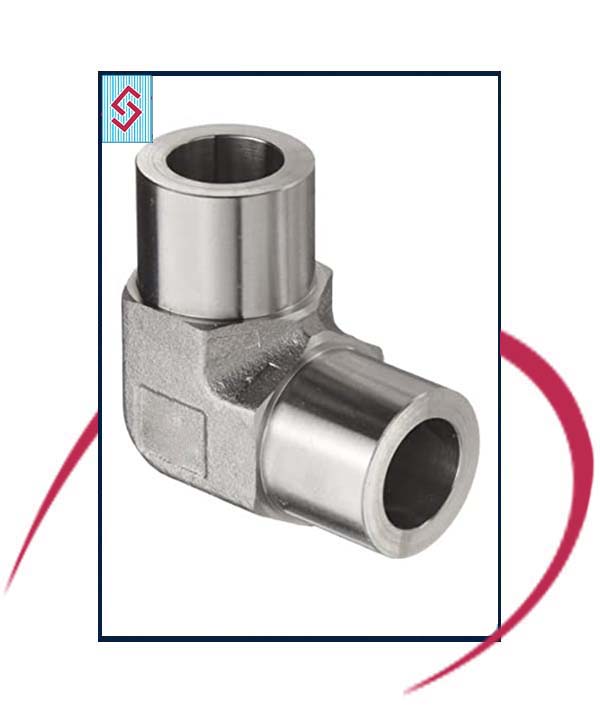

Stainless Steel 316 Tube Socket Weld Elbow Supplier

316 STAINLESS STEEL SINGLE FERRULE TUBE SOCKET WELD ELBOW EXPORTER, AUSTENITIC STAINLESS STEEL 316 TUBE SOCKET WELD ELBOW, STAINLESS STEEL 1.4401 TUBE SOCKET WELD ELBOW, STAINLESS STEEL 316 TUBE SOCKET WELD ELBOW SUPPLIERS, SS 316L HIGH PRESSURE TUBE SOCKET WELD ELBOW, 316/316L STAINLESS STEEL FERRULE TUBE SOCKET WELD ELBOW, STAINLESS STEEL S31600 TUBE SOCKET WELD ELBOW, STAINLESS STEEL 1.4436 TUBE SOCKET WELD ELBOW SUPPLIER IN INDIA

- What is Stainless Steel 316/316L Tube Socket Weld Elbow

- Standard Specification For Stainless Steel 316/316L Tube Socket Weld Elbow

- Stainless Steel 316/316L Tube Socket Weld Elbow Equivalent Grades

- Types of Stainless Steel 316/316L Tube Socket Weld Elbow

- Stainless Steel 316/316L Tube Socket Weld Elbow Chemical Composition

- Mechanical Properties of SS 316/316L Tube Socket Weld Elbow

- Other Types of 316/316L Stainless Steel Tube Socket Weld Elbow Ready Stock

- Stainless Steel Grade 316/316L Tube Socket Weld Elbow Applications

- Searches Related to Stainless Steel 316/316L Tube Socket Weld Elbow

- Export Destinations for Stainless Steel 316/316L Tube Socket Weld Elbow

Leading manufacturer and exporter company Steel Sale Co offer the fantastic Stainless Steel 316 Tube Socket Weld Elbow. The manufacturing process of our products is the same for customized and default; we follow the latest trending methods so that our products can easily use all applications. We also manufacture the different types and forms of Stainless Steel 316 Tube Socket Weld Elbow. In addition, we maintain the standard performance and quality of products. All these things help us to offer the best Stainless Steel 316 Tube Socket Weld Elbow. These weld elbows are used to connect pipes which is of different sizes.

These Socket weld elbows are used to provide direction changes in different degrees. We provide these elbows of many degrees such as 90 and 45 degree elbows which is mostly used. These products show high strength at high pressures. Due to their corrosion resistance property and high strength these products are attractive oil and gas industry. Our Stainless steel 316 Tube Socket weld Elbows shows some good qualities like less defect, good mechanical properties and withstand to high load working environment. There are advantages of these elbows are withstand to high pressure, leak proof , easy to align and weld, and no need to prepare for welding.

STAINLESS STEEL 316 1/8 X 1/8 TUBE SOCKET WELD ELBOW, STAINLESS STEEL 316/316L FERRULE TUBE SOCKET WELD ELBOW, SS 316 1/2 X 1/2 TUBE SOCKET WELD ELBOW, SS 316 TUBE SOCKET WELD ELBOW STOCKIST, SS 316 COMPRESSION TUBE SOCKET WELD ELBOW FITTING, SS 316 3/8 X 3/8 TUBE SOCKET WELD ELBOW, SS 316 HIGH QUALITY TUBE SOCKET WELD ELBOW, SS 316L TUBE X TUBE SOCKET WELD ELBOW, SS 316 HYDRAULIC TUBE SOCKET WELD ELBOW, STAINLESS STEEL 316 INDUSTRIAL TUBE SOCKET WELD ELBOW AT BEST PRICE, STAINLESS STEEL 316 TUBE SOCKET WELD ELBOW MANUFACTURER IN MUMBAI.

Steel Sale Co offers a superior process and quality of products. Stainless Steel 316/316l Tube Socket Weld Elbow offer some material expense benefits when contrasted with elective decisions, particularly for undersea extractions. Stainless Steel 316 Tube Socket Weld Elbow are generally valuable in different industries, including oil and gas, power age, mass fluid transportation, heat exchangers, synthetics, petrochemical, drugs, mash and paper ventures, and some more. These elbows are accessible in all custom sizes, measurements, norms and types according to modern demands. Dedicated time is alloted for their manufacturing so that no defect is occurred. Our Stainless Steel 316 Tube Socket Weld Elbow features are attractive as we provide corrosion cracking properties, thickness, mechanical and working properties. As we give the elbows for broad industrial applications, we maintain flexibility and reliability. Then we check our professionals’ properties, features, and objectives to finalize Stainless Steel 316 Tube Socket Weld Elbow for exporting.

Standard Specification

- Specifications

- Temperature

Up to 1000°F (537°C)

- Category

- Size Range

1/16 to 2 in.; 2 to 50 mm,

Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm

High-Pressure – 1/8 to 9/16 in.

- Pressure Ratings

Up to 11 000 psig (760 bar),

Medium-Pressure – Up to 20 000 psig (1378 bar)

High-Pressure – Up to 60 000 psig (4134 bar)

Stainless Steel 316/316L Tube Socket Weld Elbow Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Types of Stainless Steel 316/316L Tube Socket Weld Elbow

Compression Tube Socket Weld Elbow

- SS 1.4435 Compression Tube Socket Weld Elbow Manufacturer

- SS 316L Compression Tube Socket Weld Elbow

- Stainless Steel S31603 Compression Tube Socket Weld Elbow

- SS 1.4401 Compression Tube Socket Weld Elbow

- 316 Stainless Steel Compression Tube Socket Weld Elbow Supplier

- SS 316 Compression Tube Socket Weld Elbow Stockist

- SS S31600 Compression Tube Socket Weld Elbow

- 316/316L SS Compression Tube Socket Weld Elbow Exporter

Instrumentation Tube Socket Weld Elbow

- 316 Stainless Steel Instrumentation Tube Socket Weld Elbow Supplier

- SS S31600 Instrumentation Tube Socket Weld Elbow Manufacturer

- SS 1.4404 Instrumentation Tube Socket Weld Elbow

- Stainless Steel 316L Instrumentation Tube Socket Weld Elbow

- SS 316/316L Instrumentation Tube Socket Weld Elbow

- 316 SS Instrumentation Tube Socket Weld Elbow Exporter

- SS S31603 Instrumentation Tube Socket Weld Elbow

- SS 1.4436 Instrumentation Tube Socket Weld Elbow Stockist

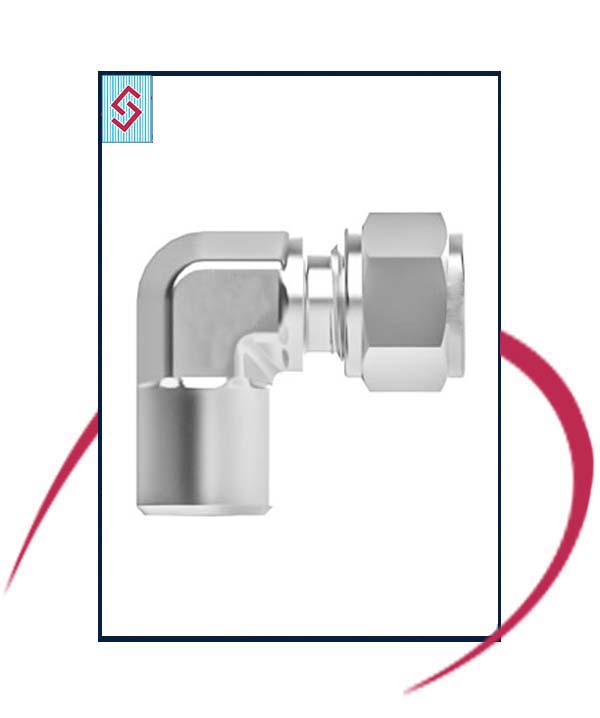

Ferrule Tube Socket Weld Elbow

- SS 1.4401 Ferrule Tube Socket Weld Elbow

- SS S31603 Ferrule Tube Socket Weld Elbow

- 316 Stainless Steel Ferrule Tube Socket Weld Elbow Supplier

- SS 316/316L Ferrule Tube Socket Weld Elbow Stockist

- S31600 SS Ferrule Tube Socket Weld Elbow Exporter

- SS 1.4435 Ferrule Tube Socket Weld Elbow Manufacturer

- SS 316 Ferrule Tube Socket Weld Elbow

- Stainless Steel 316L Ferrule Tube Socket Weld Elbow

Stainless Steel 316/316L Tube Socket Weld Elbow Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

Stainless Steel 316/316L Tube Socket Weld Elbow Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 316/316L Tube Socket Weld Elbow

- Stainless Steel 1.4436 Tube Socket Weld Elbow

- UNS S31603 Tube Socketweld Elbow in Mumbai

- SS 1.4404 Tube Socket Weld Elbow Dealer in India

- Stainless Steel Grade 316L Tube Socket Weld Elbow

- 316 Stainless Steel Tube Socket Weld Elbow Manufacturer

- 316/316L Stainless Steel Tube X Socket Weld Elbow

- SS Grade 316 Industrial Tube Socket Weld Elbow

- SS 316 Socketweld Elbow Supplier in India

- SS 316 1/4 Tube Socket Weld Elbow

- SS 1.4435 Tube Socket Weld Elbow Stockholder

- Stainless Steel 316L 3/8 Tube Socket Weld Elbow

- SS 316 Tube Socketweld Elbow Stockist in Mumbai

- UNS S31600 Tube Socket Weld Elbow Exporters

- 316/316L Stainless Steel Tube Socket Weld Elbow Supplier

- SS 1.4401 1/2 Tube Socket Weld Elbow Manufacturer

- SS S31600 1/8 Tube Socket Weld Elbow

Stainless Steel 316/316L Tube Socket Weld Elbow Application Industries

Searches related to Stainless Steel 316/316L Tube Socket Weld Elbow

We Export SS 316/316L Tube Socket Weld Elbow to Following Destinations

Thailand, Japan, Portugal, Bangladesh, Israel, Iraq, Spain, Trinidad & Tobago, Chile, Singapore, Slovakia, Sweden, Lebanon, Iran, Austria, Nigeria, Libya, Vietnam, Estonia, Pakistan, Russia, Taiwan, Peru, Poland, Bahrain, Canada, Ecuador, Chile, Hungary, Mongolia, Hong Kong, Colombia, United States, Poland, Bolivia, South Korea, Bhutan, United Arab Emirates, Oman, Turkey, Qatar, Venezuela, France, Lithuania, South Africa, Saudi Arabia, Brazil, Sri Lanka, Costa Rica, Algeria, Malaysia, Tunisia, Mexico, Australia, Norway, Mexico, Iran, Yemen, Romania, Belgium, Indonesia, Italy, Finland, Czech Republic, Nigeria, Croatia, New Zealand, China, Kenya, Kazakhstan, Belarus, Netherlands, Afghanistan, Greece, Serbia, Jordan, Ukraine, Philippines, United Kingdom, Switzerland, Azerbaijan, Kuwait, Ghana, Argentina, Angola, Morocco, Gabon, Bulgaria, Egypt, Denmark.

Manama, Madrid, Hyderabad, Kolkata, Brisbane, Indore, Surat, Atyrau, Pune, Vung Tau, Istanbul, Colombo, Hanoi, Courbevoie, Kuala Lumpur, Navi Mumbai, Bogota, Gimhae-si, La Victoria, Ernakulam, Seoul, Nagpur, Kanpur, Cairo, Port-of-Spain, Milan, Ludhiana, Ho Chi Minh City, Bangkok, Ahvaz, Kuwait City, Riyadh, New Delhi, Melbourne, Jamshedpur, Edmonton, Perth, Calgary, New York, Dallas, Geoje-si, Busan, Lagos, Noida, Thiruvananthapuram, Doha, Nashik, Dammam, Ahmedabad, Granada, Los Angeles, Jakarta, Caracas, Bengaluru, Secunderabad, Rio de Janeiro, Aberdeen, Chiyoda, Jeddah, Houston, Howrah, Pimpri-Chinchwad, Gurgaon, Algiers, Muscat, Chandigarh, Petaling Jaya, Sharjah, Coimbatore, Faridabad, Al Jubail, Sydney, Haryana, Bhopal, Chennai, Thane, Santiago, Ankara, Dubai, Lahore, Tehran, Vadodara, Al Khobar, Toronto, Visakhapatnam, Ulsan, Baroda, Rajkot, Mumbai, Montreal, Ranchi, Abu Dhabi, Jaipur.